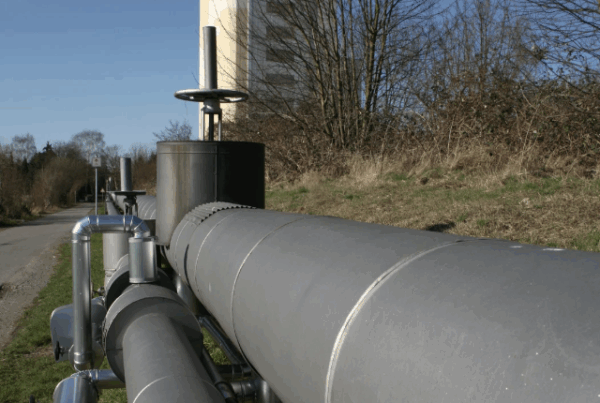

The White House says that six-ten million homes are still being served by lead pipes leading to ill effects of contaminated water felt by residents. To rehabilitate and repair such aging plumbing systems, epoxy pipe lining has become a popular solution.

Known for its durability and cost-effectiveness, this method involves coating the interior of pipes with a layer of epoxy resin to seal cracks, prevent leaks, and extend the lifespan of existing plumbing. But how long does epoxy pipe lining last?

While many factors influence its longevity, proper installation and maintenance can lead to decades of reliable service. Here is what you need to know.

The Expected Lifespan of Epoxy Pipe Lining

Epoxy pipe lining lasts for a longer time than traditional pipe replacement, which makes epoxy lining a practical solution for residential, commercial, and industrial properties dealing with aging pipes or recurring plumbing issues.

Traditional pipe replacement, which can be invasive, time-consuming, and costly, should be avoided.

Advantages of Epoxy Pipe Lining for Longevity

Why should property managers and facility owners consider epoxy or trenchless pipe lining for their buildings? There are many reasons.

Corrosion Resistance

One of the main reasons epoxy lining lasts so long is its corrosion resistance.

According to Science Direct, epoxy resin coatings have excellent mechanical strength. They adhere extremely well to many kinds of surfaces. Since they are resistant to chemicals and corrosion-resistant, they are a great attractive alternative to traditional pipe replacement.

Unlike traditional materials like metal pipes, epoxy resin does not rust or degrade when exposed to water or minerals, making it particularly suitable for areas with hard water.

Leak Prevention

Epoxy effectively seals existing cracks, joints, and weak points within pipes, preventing leaks. Creating a smooth, seamless interior reduces the likelihood of future damage caused by pressure fluctuations or external factors.

Reduced Wear and Tear

The epoxy coating creates a non-reactive surface that minimizes friction and buildup of debris, scale, or rust. This not only improves water flow but also reduces the strain on the pipes, extending their functional life.

Signs That It May Be Time for Repairs or Replacement

While epoxy pipe lining can last for decades, it’s important to monitor your plumbing system for signs of wear. Examples include:

- Reduced water pressure

- Persistent leaks

- Discolored water

- Unusual odors or tastes

These issues could indicate that the epoxy lining is beginning to deteriorate or that the original pipe has sustained additional damage.

Proper Maintenance Extends Lifespan

To maximize the lifespan of epoxy pipe lining, regular maintenance is key. Consider these tips.

- Schedule periodic plumbing inspections to identify potential issues early

- Avoid harsh chemical cleaners that could erode the epoxy over time

- Maintain stable water pressure to minimize strain on the pipes

Trenchless Pipe Replacement – Best Preventative Maintenance to Consider

As a property manager or building owner, you understand the importance of long-term solutions. Traditional pipe replacement methods are no longer necessary when trenchless pipe replacement is available to you.

Advantage Reline is the leader in trenchless pipe repair. We have been innovating in the epoxy pipe lining business for 20 years now and have come with up proprietary pipe repair techniques and materials.

Need pipe repair for your facility? Contact our team to learn more about preventative maintenance steps today and how trenchless solutions can benefit your property.