Pipelines are the backbone of modern infrastructure, facilitating the transportation of vital resources like oil, gas, and water. To ensure their longevity and optimal performance, pipes often require protective measures against corrosion and abrasion. Two commonly used methods for safeguarding pipelines are coating and lining.

In this blog, we will dive into the purpose, benefits, and explaining the key differences between these two essential techniques.

What is Pipe Coating?

Pipe coating is the process of applying a protective layer to the external surface of a pipe. This external shield helps prevent corrosion, erosion, and other forms of damage caused by external environmental factors.

The coatings are typically applied in liquid form and can be either single or multi-layered, depending on the level of protection required. These coatings are typically applied using various techniques, including painting, spraying, or dipping, and they serve as a barrier between the pipe’s surface and the surrounding environment.

What is the Purpose of Pipe Coating?

The primary purpose of coating pipes is to prevent corrosion caused by exposure to moisture, chemicals, and atmospheric conditions. Corrosion can lead to structural weakening, leaks, and even pipe failure.

Benefits of Pipe Coating

Pipe coating offers several benefits, such as corrosion resistance, extending the pipeline’s lifespan, and reducing maintenance costs. It provides additional protection, especially in aggressive environments, enhancing the pipeline’s durability.

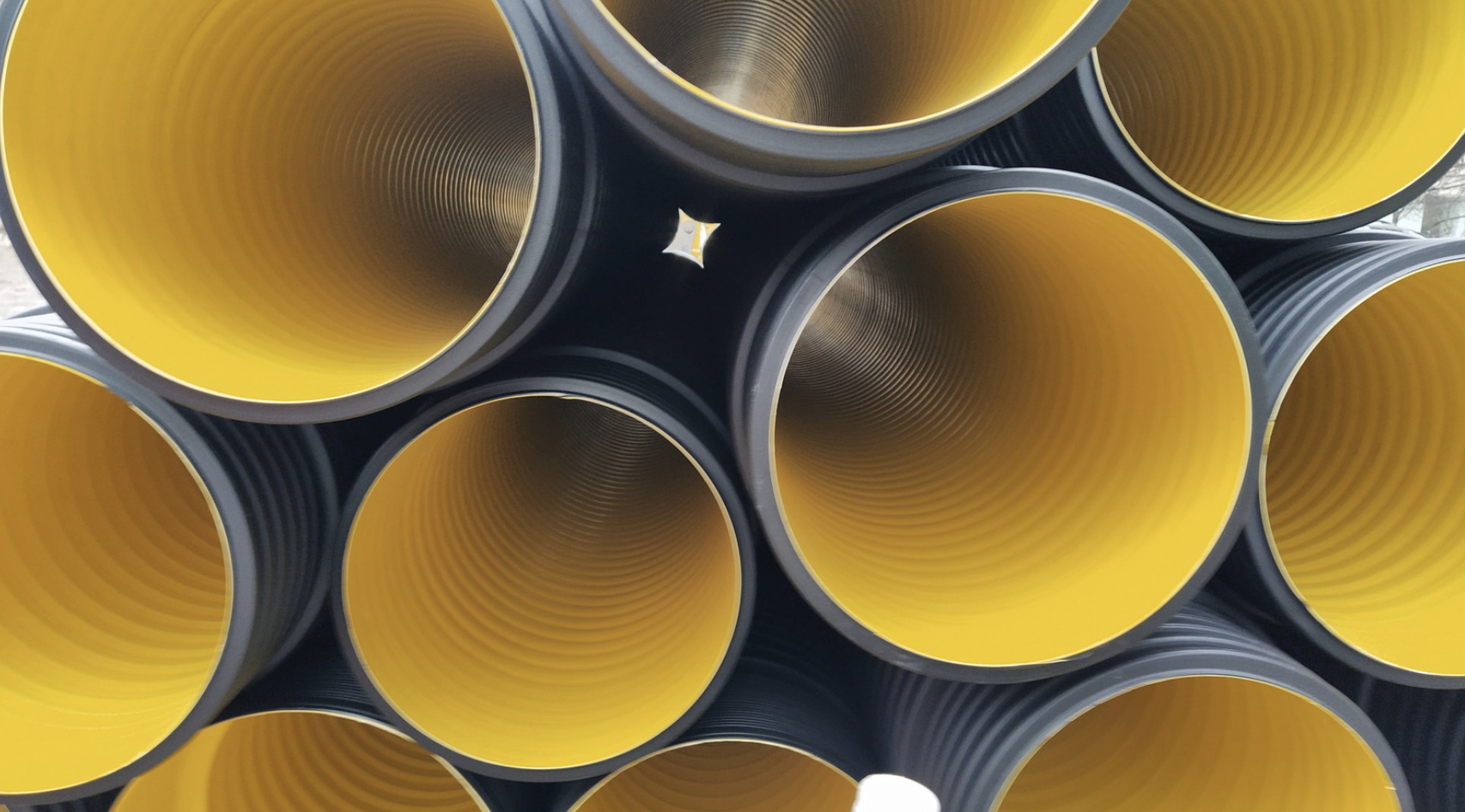

What is Pipe Lining?

Pipe lining is a method used to protect and rehabilitate pipelines by applying a protective layer to the inner surface of the pipe. It involves the application of a protective lining material, typically cement mortar, epoxy, or thermoplastic liners, to the inner surface of the existing pipe. The longevity of pipe lining can vary depending on factors such as the lining material, the quality of installation, and the conditions within the pipeline. However, it can often last for several decades, making it a cost-effective solution for pipeline maintenance.

What is the Purpose of Pipe Lining?

The primary purpose of pipe lining is to improve the flow efficiency of the pipe line and extend its operational life.

Benefits of Pipe Lining

Pipe lining enhances the hydraulic performance of the pipeline, reducing friction and ensuring a smoother flow of fluids or gases. It also prevents the build-up of deposits and rust on the inner surface, which can lead to reduced flow capacity and maintenance headaches.

The Key Differences Between Pipe Coating vs Pipe Lining

While both pipe coating and pipe lining aim to protect pipelines, they have distinct differences:

- Location: Pipe coating is applied to the external surface of the pipe, protecting it from external factors, whereas pipe lining is applied internally, improving the inner surface.

- Purpose: Pipe coating primarily guards against external threats like corrosion and physical damage, while pipe lining focuses on improving hydraulic performance and preventing internal decay.

- Materials: Pipe coating materials typically include epoxy, polyethylene, or coal tar enamel, while pipe lining may use cement mortar, epoxy, or thermoplastic liners.

- Benefits: Pipe coating extends the external durability and reduces maintenance costs, while pipe lining improves flow efficiency and prevents internal corrosion, enhancing operational efficiency.

Conclusion

In the world of pipelines, understanding the differences between pipe coating and pipe lining is crucial for effective maintenance and protection. By utilizing the right technique for the specific requirements of your pipeline, you can optimize its performance and longevity, reducing the overall cost of pipeline ownership and maintenance. With our expertise in trenchless pipe repairs, we offer cost-effective and efficient solutions that minimize disruption and ensure the longevity of your pipes. Contact us today!