A versatile liner system for the transport of liquid and gaseous media.

The flexible liner, reinforced with aramid fabric, and the specifically developed connectors form a high-performance potable-safe solution for the trenchless rehabilitation of pressure pipes or for setting up a robust independently placeable flexible line.

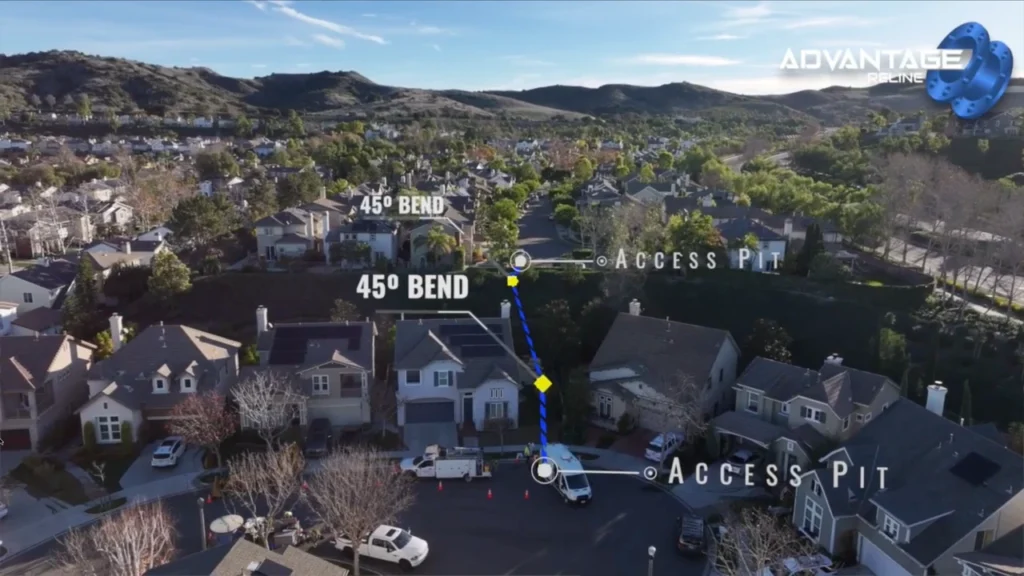

How Primus Line works.

For sustainable and reliable pipeline rehabilitation, Primus Line™ employs innovative trenchless technology to restore pressure pipelines for water, sewer, gas, and oil. Its unique flexible, high-pressure hose system, featuring a smooth inner lining, optimizes flow and pressure while protecting existing pipes from further abrasion and corrosion. This method ensures secure, loss-free conveyance of sensitive media like drinking water, safeguarding this essential resource for water authorities and future generations.

Features.

Applications.

Common uses of Primus Line include water (pressure & potable), sanitary, sewer and gas & oil pipe repair and rehabilitation. Let our experts help you determine the right solution for your situation.

Testimonials.

Case Studies